Contact Us

Products/Services

Temperature Transmitters

Wire Harnesses

Temperature Sensors

Fiber Optic Sensor Systems (Partner Company)

Thermocouple/Extension Wire

Temperature and Process Controllers

Specialty Metals

Technical Resources

Nanmac Sensors in Tokamak Reactor SystemComparison of Temperature Sensors & Response TimesProperties of Refractory & Ceramic MaterialsRefractory Metal Resistance to Corrosive Materials - GuideThermocouple Alloy - Use & CharacteristicsTemperature Conversion Chart - Melting Points of MetalsA ultra fast thermocouple used to measure: squibs, ignitors, propellants, and rocket nozzlesNanmac High Performance ThermocouplesThermocouples and Extension Grade WireLeading Cause of Errors in Temperature MeasurementThermocouple Standards & CalibrationsThermocouples in Furnaces & OvensSelecting the Right ThermocoupleMold temperature and heat flux measurements during the production of glass containersCare & Use of Nanmac Eroding ThermocouplesNanmac Short Form Article on Using ASTM StandardsWhen Thermocouples Fail

Certifications / ISO/IEC 17025:2017 Accreditation

Page 1

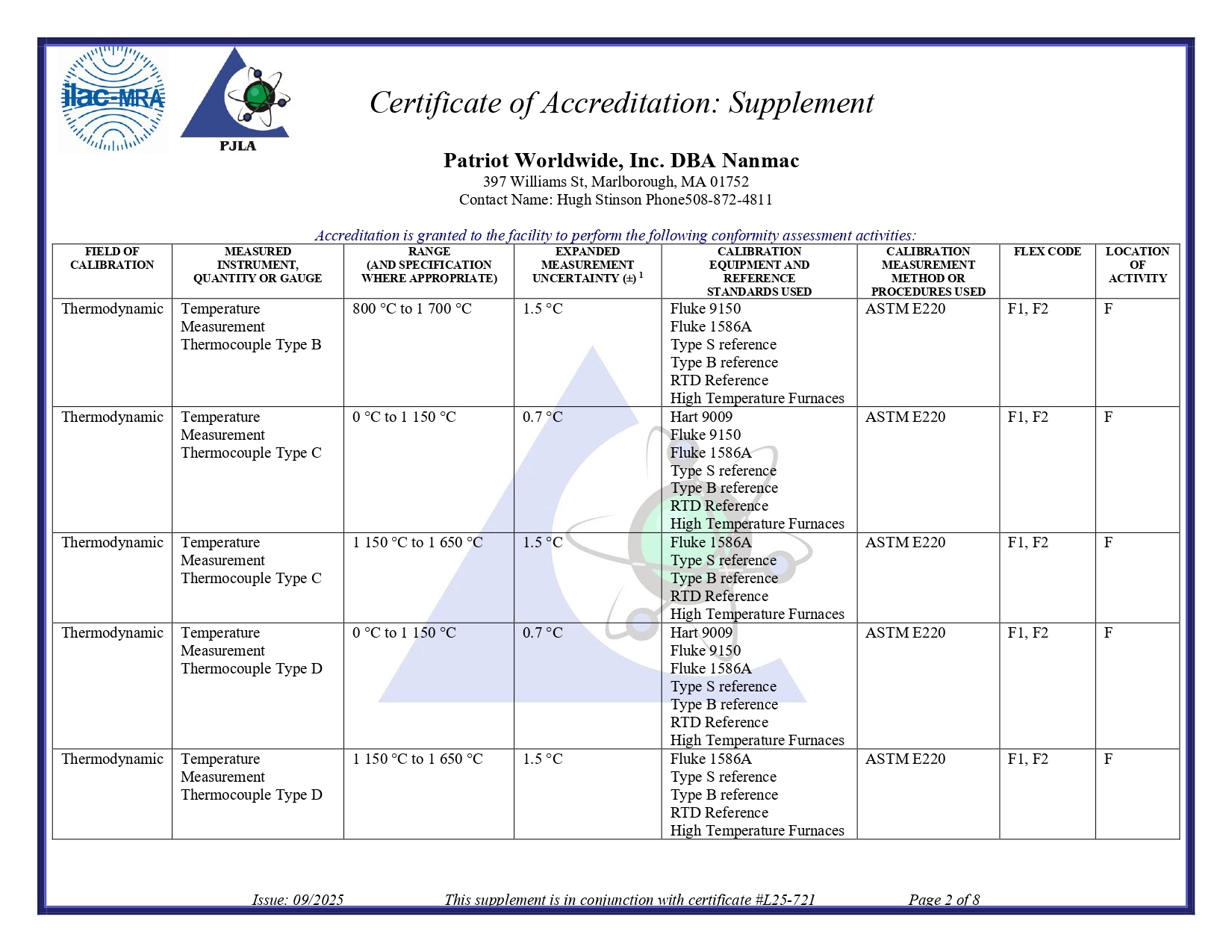

Page 2

Page 3

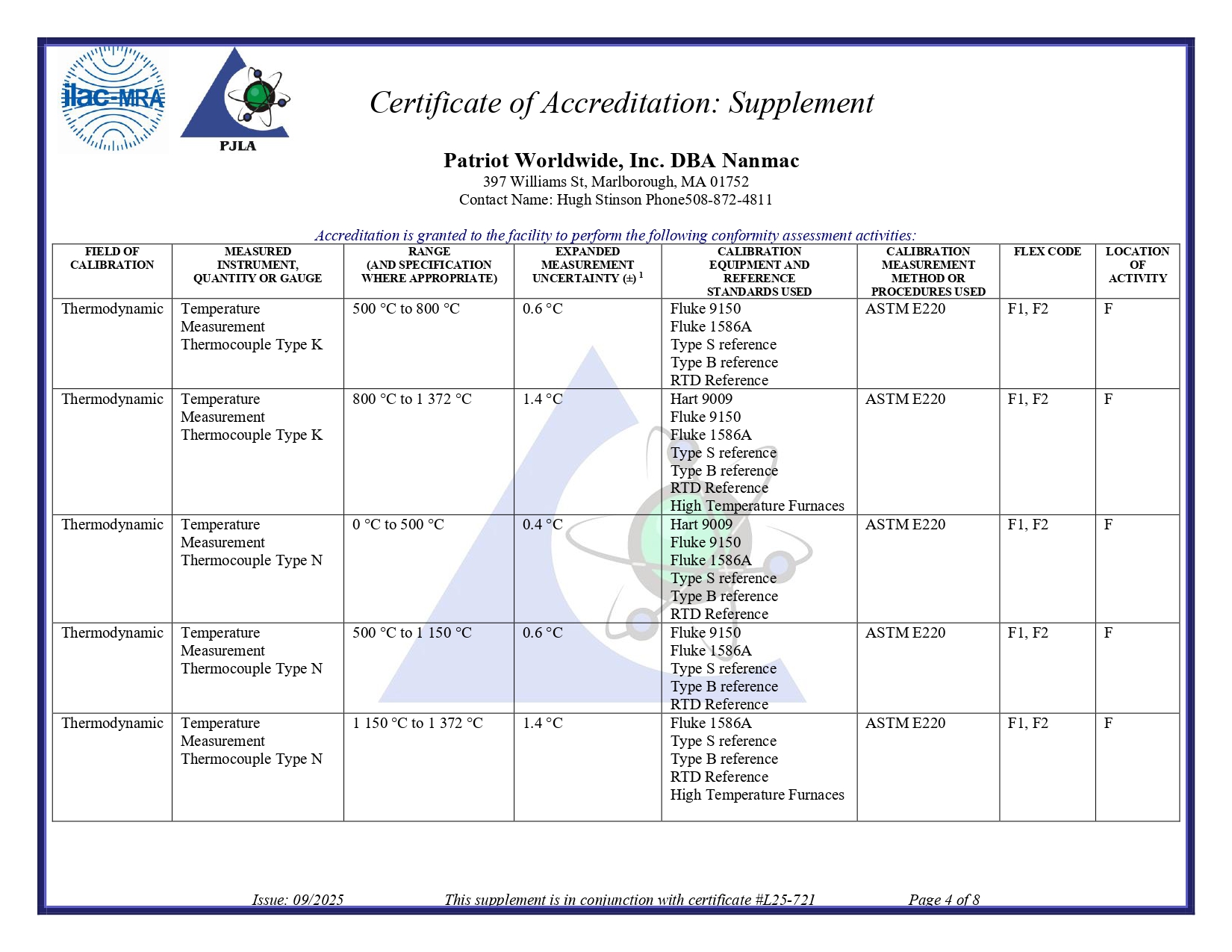

Page 4

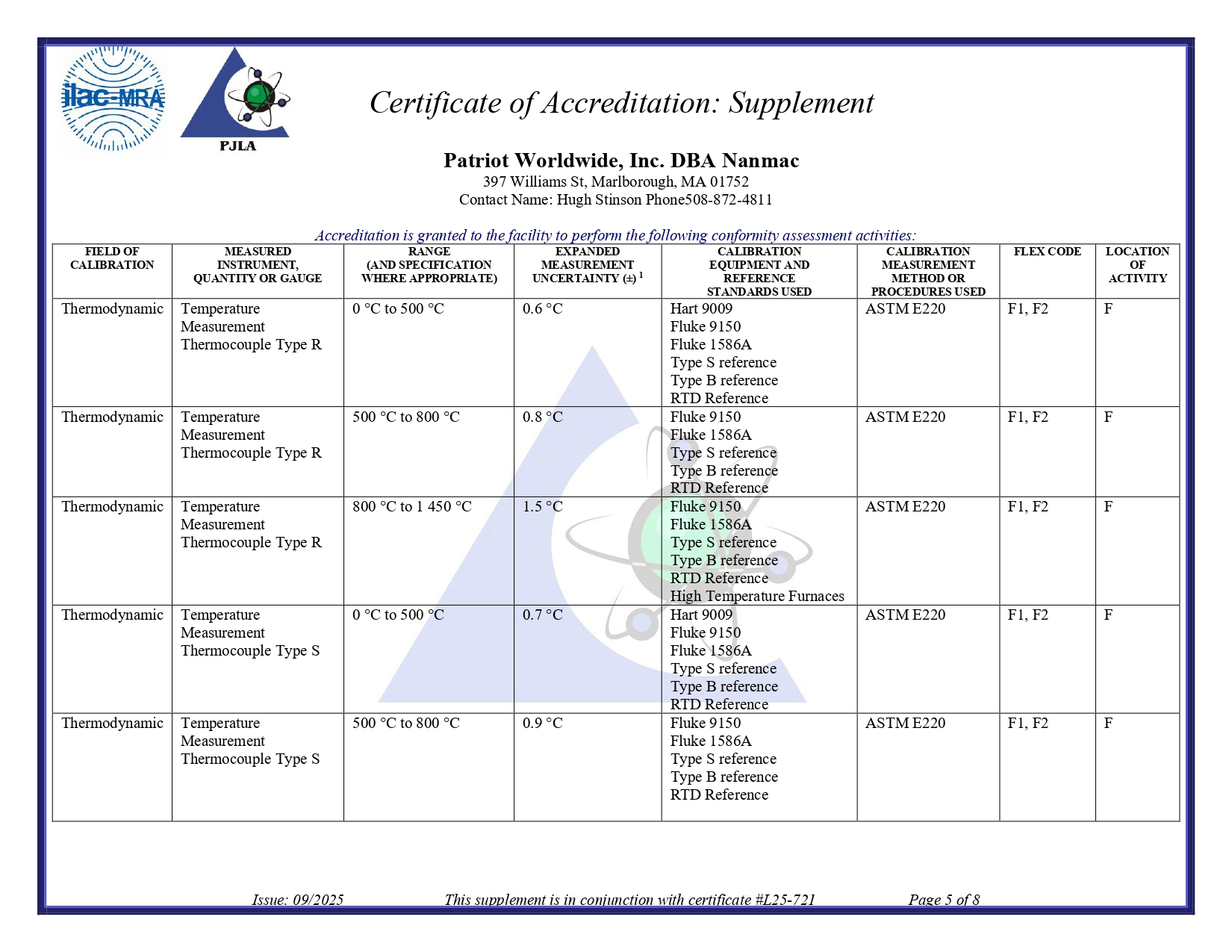

Page 5

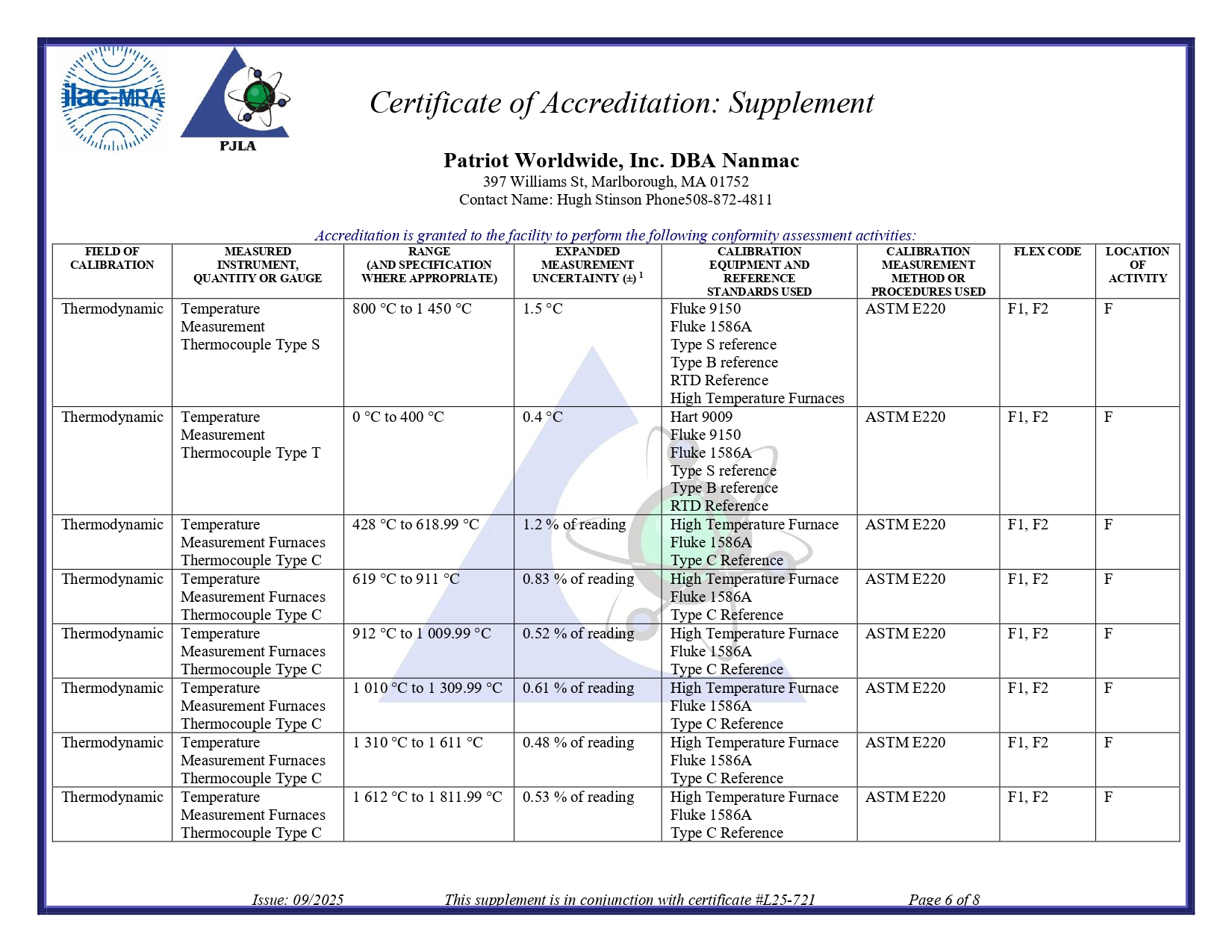

Page 6

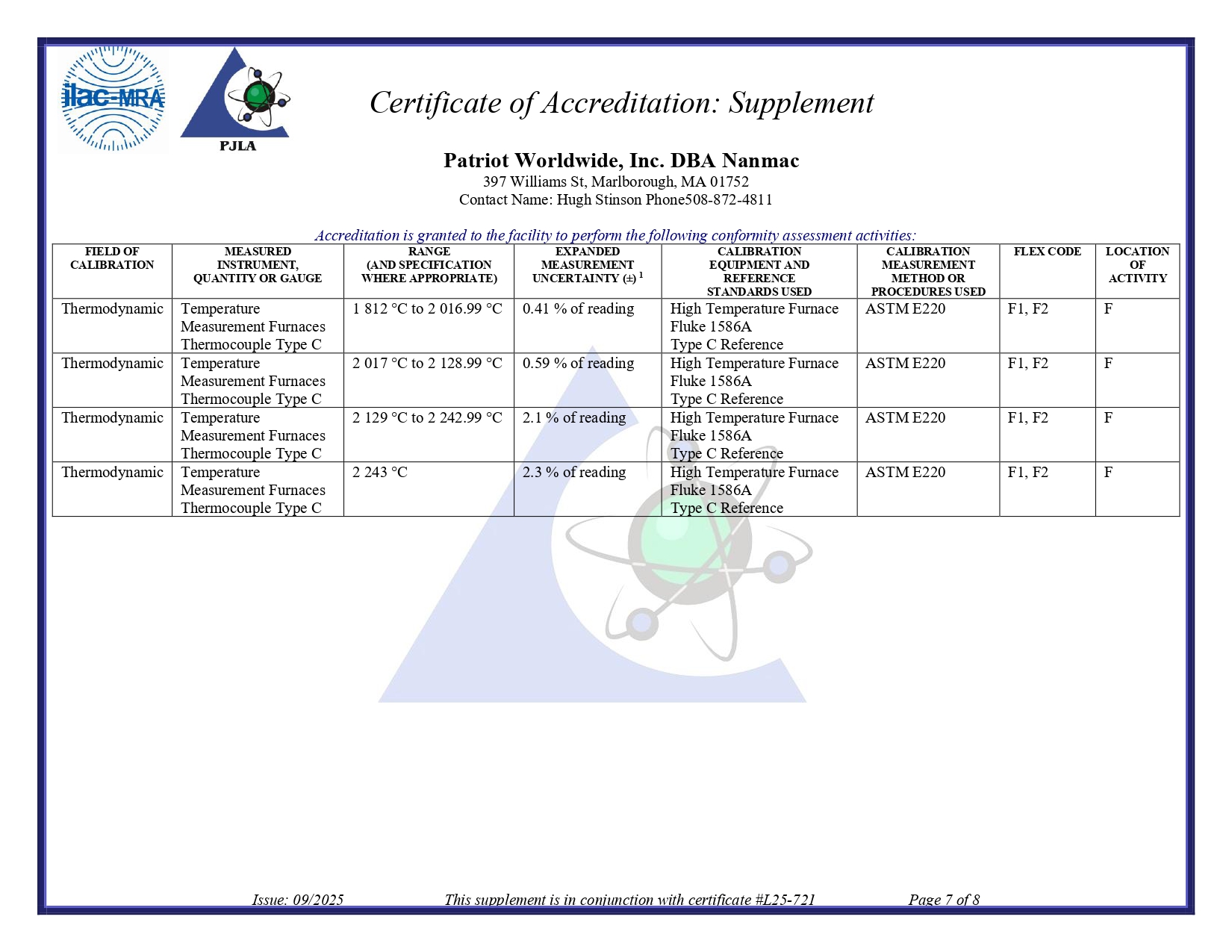

Page 7

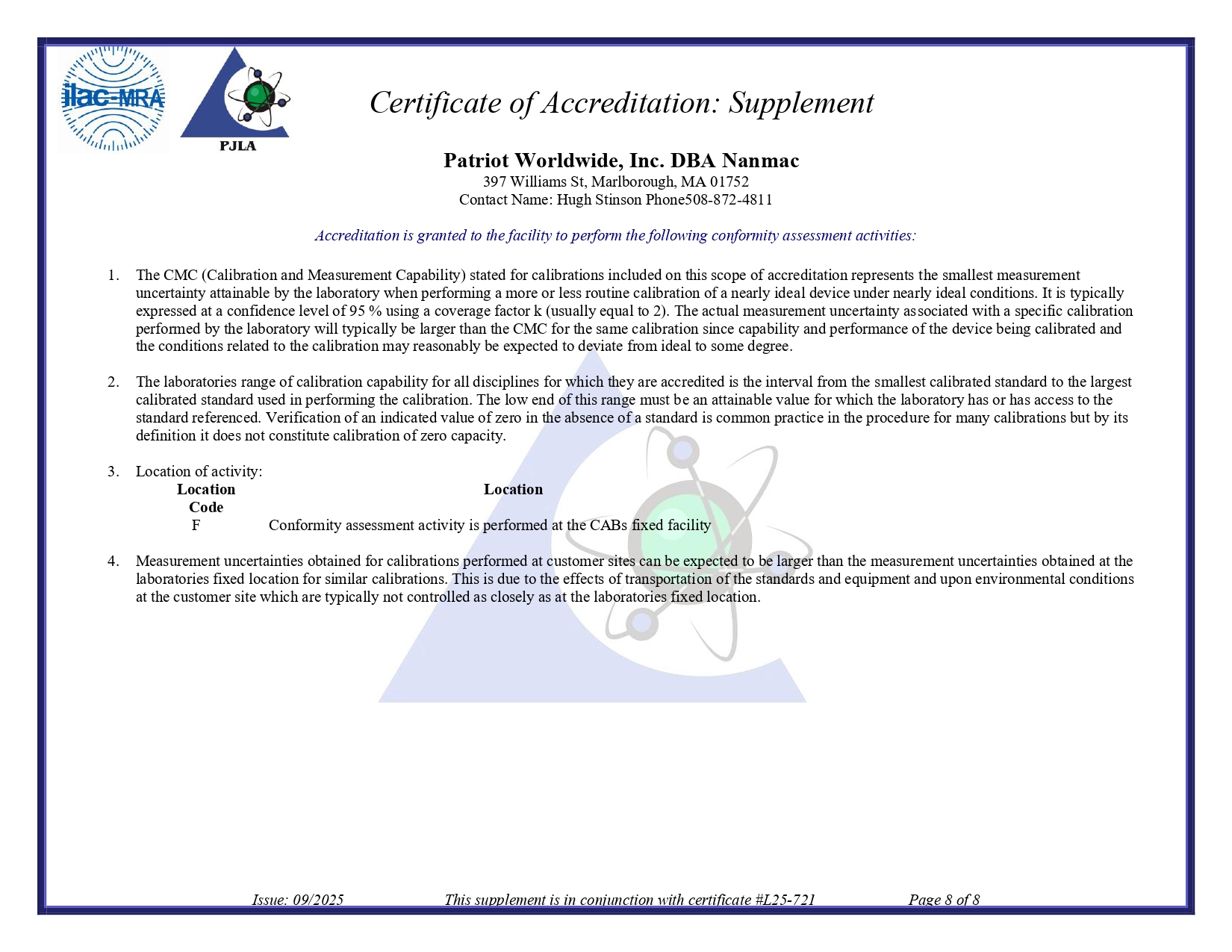

Page 8

© 2025 Nanmac Corporation