Contact Us

Temperature Transmitters

Wire Harnesses

Temperature Sensors

Fiber Optic Sensor Systems (Partner Company)

Thermocouple/Extension Wire

Temperature and Process Controllers

Specialty Metals

Products / Exposed & Bare Wire Thermocouples / Micro-Thermocouples

Micro-Thermocouples

Nanmac Micro-Thermocouples (A14C Series) are flexible fine gage thermocouple wires used whenever fast, accurate temperature measurements are required. The thermocouple consists of two dissimilar metals, joined together at one end. A small voltage is produced by the two metals, which can be measured and interpreted by a control system. The dissimilar metals are individually insulated, and an overcoat is present to maintain an intimate bifilar configuration. Custom applications including medical, aerospace, and others which require micro sensor system requirements.

Key Features

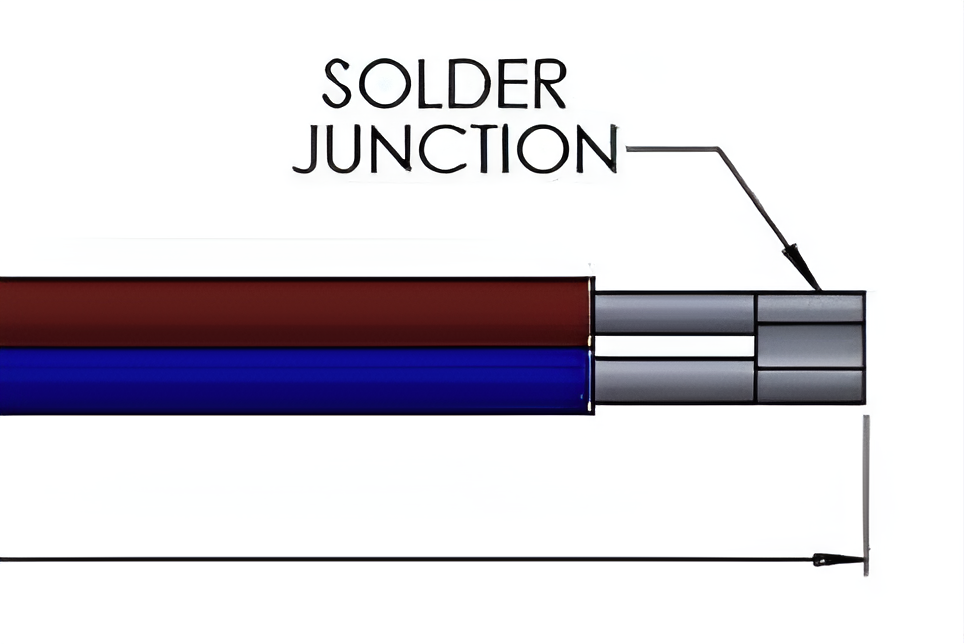

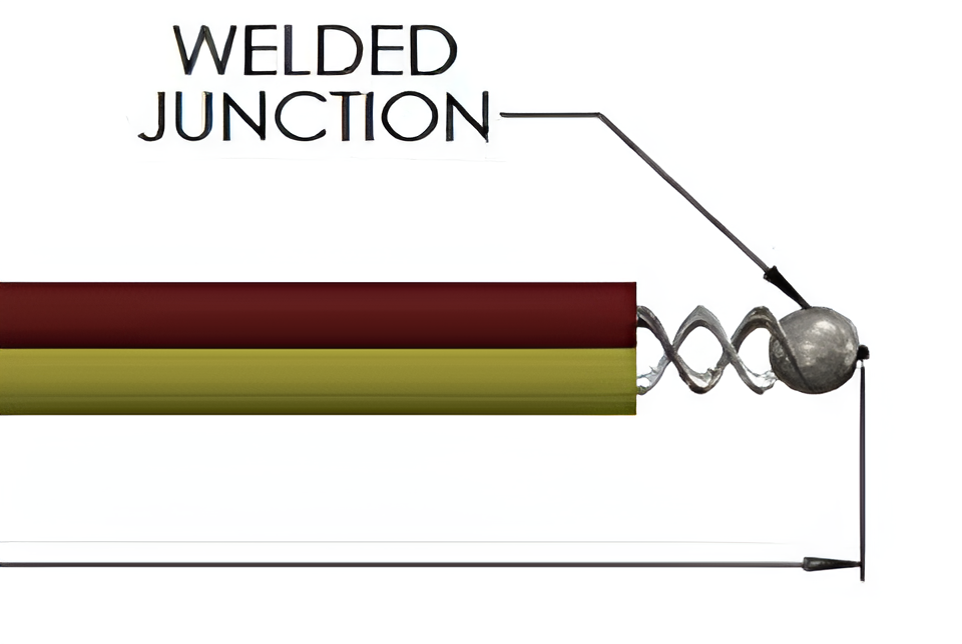

Welded or soldered

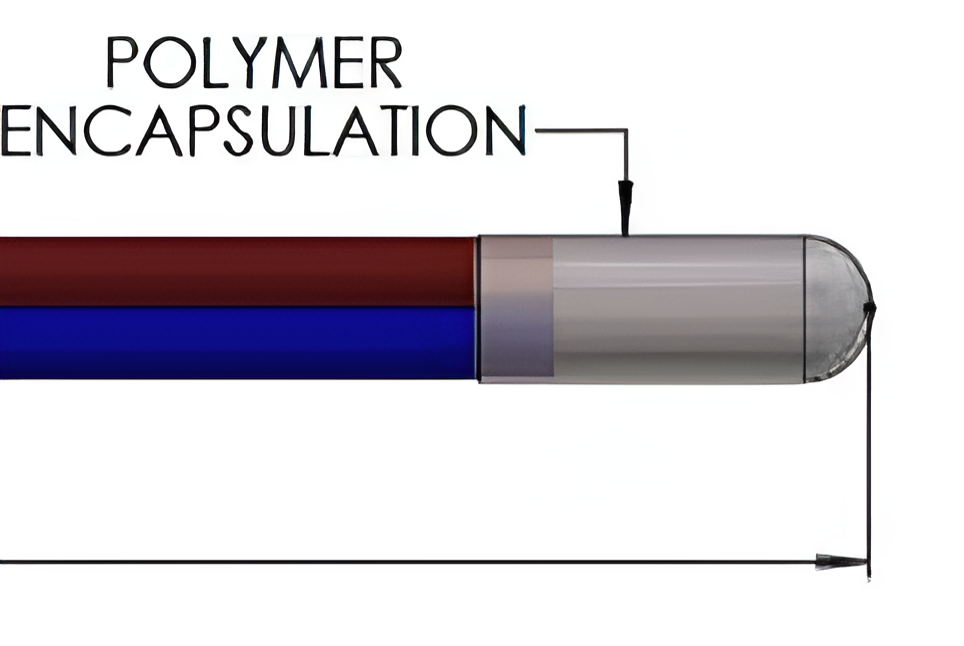

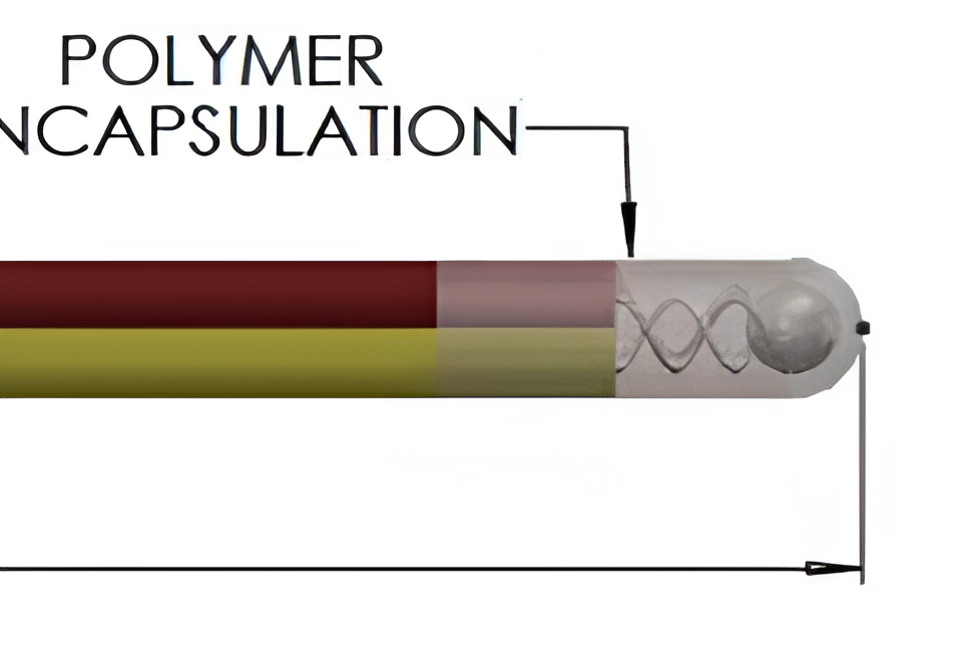

Encapsulated or bare

Bifilar construction

Moisture seal (encapsulated only)

Flexible tip

High volume, low cost

Custom packaging

Medical Applications

General Information

A14C-1

- Wire strip length: 0.50" +/- 0.25"

- Solder joint length: 0.10" Max

- Encapsulation length: 0.25" Max

- Wire length tolerance: +/- 3.0"

- Type K only

A14C-2

- Wire strip length: 0.50" +/- 0.25"

- Solder joint length: 0.10" Max

- Encapsulation length: 0.25" Max

- Wire length tolerance: +/- 3.0"

- Type K only

A14C-3

- Wire strip length: 0.50" +/- 0.25"

- Solder joint length: 0.10" Max

- Encapsulation length: 0.25" Max

- Wire length tolerance: +/- 3.0"

- Type T only. Encapsulation rated to 200°C

A14C-4

- Wire strip length: 0.50" +/- 0.25"

- Solder joint length: 0.10" Max

- Encapsulation length: 0.25" Max

- Wire length tolerance: +/- 3.0"

- Type K only. Encapsulation rated to 200°C

A14C-5

- Wire strip length: 0.50" +/- 0.25"

- Solder joint length: 0.10" Max

- Encapsulation length: 0.25" Max

- Wire length tolerance: +/- 3.0"

- Type K only. Junction epoxy potted in ss hypo tube. Rated to 140°C

A14C-6

- Wire strip length: 0.50" +/- 0.25"

- Solder joint length: 0.10" Max

- Encapsulation length: 0.25" Max

- Wire length tolerance: +/- 3.0"

- Type T only. Junction epoxy potted in polyimide tube. Rated to 150°C

Performance Specifications

| General | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wire Strip Length (Tail) | 0.50” ± 0.25” | ||||||||||

| Solder Joint Length | 0.10” Max | ||||||||||

| Encapsulation Length | 0.25” Max | ||||||||||

| Encapsulation Profile | 0.010” Max. for 44 AWG 0.013” Max. for 40 AWG 0.015” Max. for 38 AWG 0.017” Max. for 36 AWG | ||||||||||

| Wire length tolerance | ± 3.0” | ||||||||||

| Packaging | Sensors wrapped on white plastic spools | ||||||||||

| Note: Specifications listed above are standard. Other options are available upon request. Consult factory for details. | |||||||||||

| Wire Gage | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thermocouple Gauge (AWG) | Bare Conductor Diameter | Bifilar Insulated Wire Profile | |||||||||

| 44 | 0.002" | 0.0030" x 0.0060" (H x W) Max" | |||||||||

| 40 | 0.003" | 0.0041" x 0.0081" (H x W) Max" | |||||||||

| 38 | 0.004" | 0.0052" x 0.0104" (H x W) Max" | |||||||||

| 36 | 0.005" | 0.0065" x 0.0128" (H x W) Max" | |||||||||

| Thermocouple | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thermocouple Sensor Type | Thermocouple | ||||||||||

| Thermocouple Type | K, T | ||||||||||

| Thermocouple Sensor Package | Spool | ||||||||||

| Thermocouple Sensor Connector Type | Stripped Lead Ends | ||||||||||

| Style | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Style # | Junction Type | Junction Information | Termination (Profile) | Notes | Wire Insulation | ||||||

| 1 | Soldered (Lead Free) | Bare | Flat | Polyesterimide | |||||||

| 2 | Welded | Bare | Round | Polyimide | |||||||

| 3 | Soldered (Lead Free) | Insulated | Flat | Encapsulation Rated to 200°C | Polyesterimide | ||||||

| 4 | Welded | Insulated | Round | Encapsulation Rated to 200°C | Polyimide | ||||||

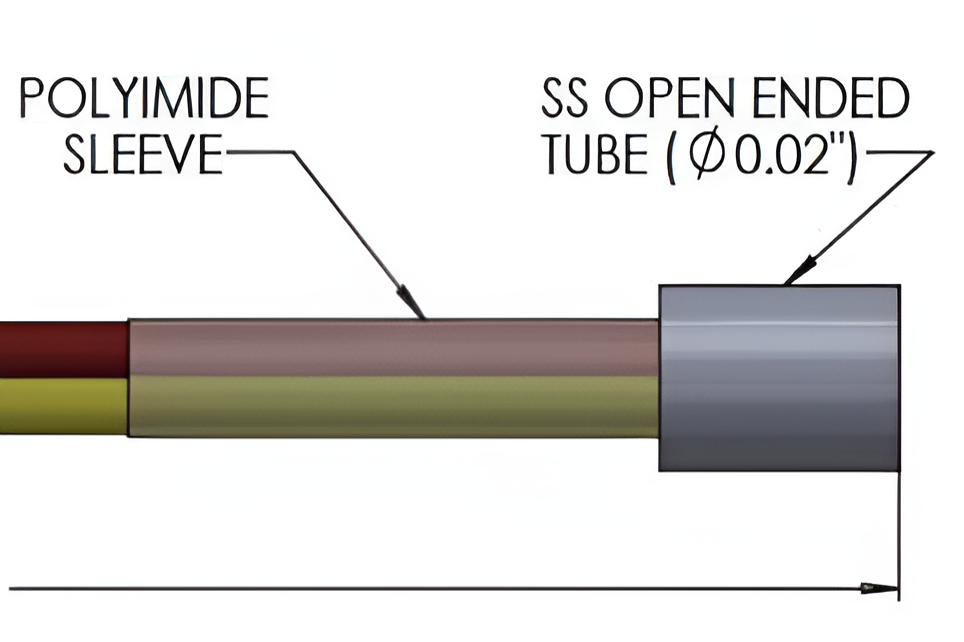

| 5 | Welded | Insulated | Round | Junction Epoxy Potted in SS Hypo Tube. Rated to 140°C | Polyimide | ||||||

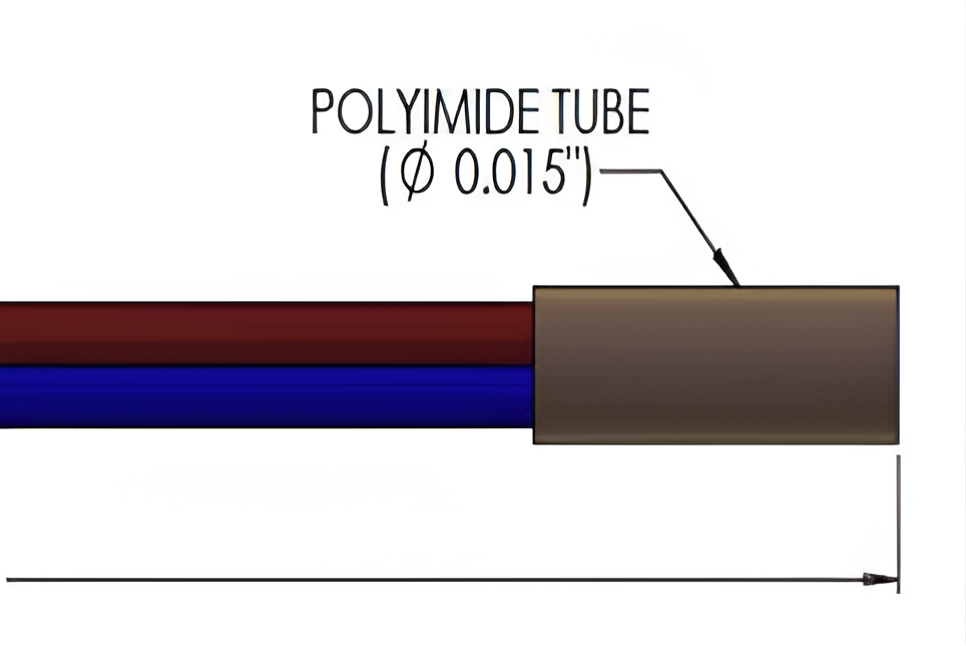

| 6 | Soldered | Insulated | Round | Junction Epoxy Potted in Polyimide Tube. Rated to 150°C | Polyesterimide | ||||||

Part Number Configuration

A14C-A-B-C-D:

Legend:- A: select the style number

- B: insert the calibration type T or K

- C: insert the wire gage: 44, 40, 38 or 36

- D: specify the probe length in inches

Note: For custom probes or custom probe lengths please contact [email protected]. Not all configurations are available, contact us for a valid part number configuration.

© 2025 Nanmac Corporation